Mirka, choosing a sustainable void fill solution with Renew air bags | Case Study

Mirka Ltd is a world leader in surface finishing technology and offers a broad range of groundbreaking sanding solutions for the surface finishing and precision industry.

The Challenge

Mirka is a globally growing company with 18 subsidiaries in Europe, the Middle East, North and South America and Asia. Headquarters and production are located in Finland. Over 97% of their products are exported and sold in more than 100 countries.

To deliver its products, Mirka used standard air bags, which offered the right protection but were not sustainable. Mirka therefore went in search of an ecologically sound alternative.

The Solution

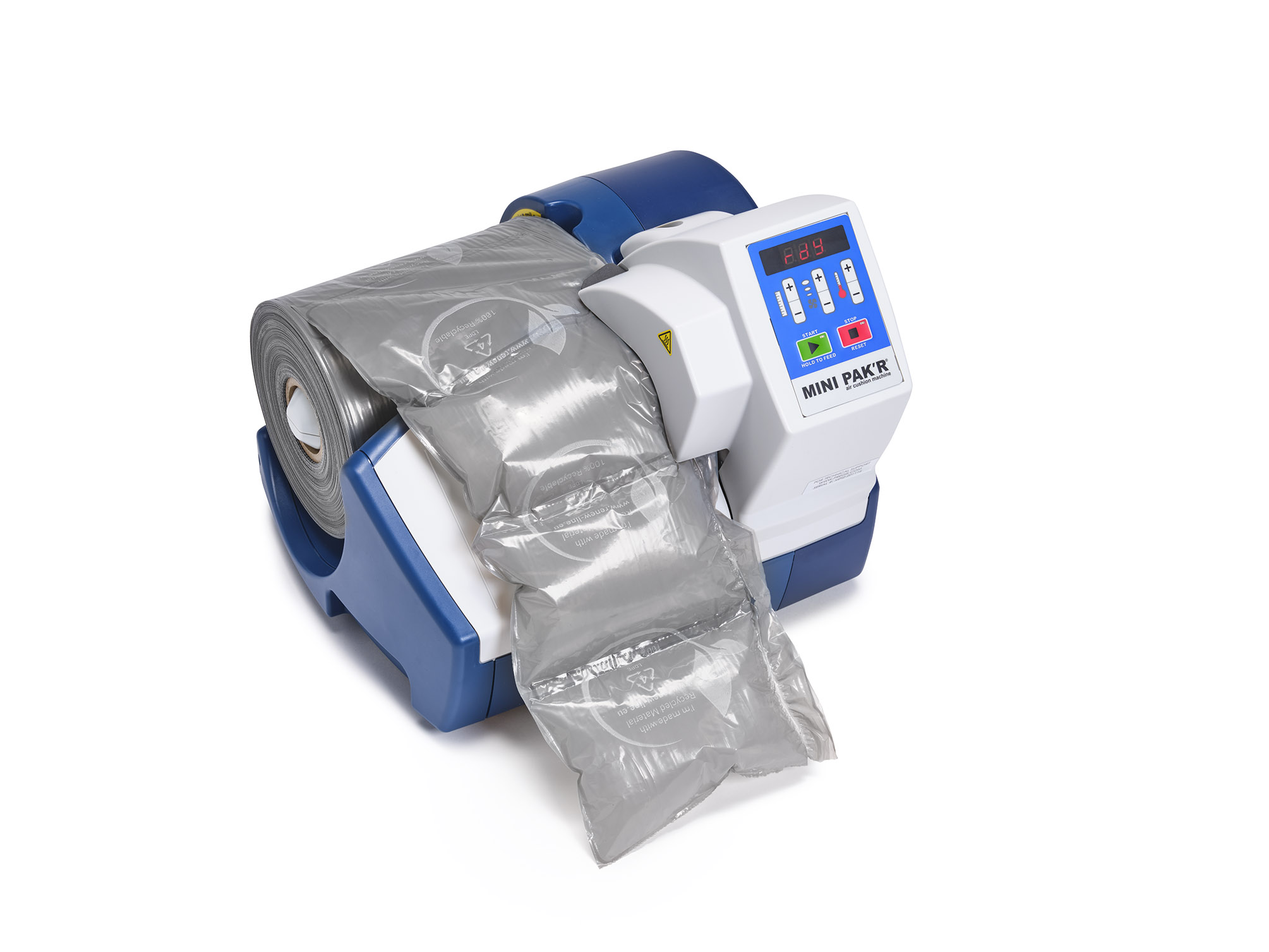

Pregis together with Topa Packaging reviewed the company’s proper protective packaging solution, as well as its packing operation. Mirka was offered the MINI PAK'R V3 machine in combination with the grey, environmentally friendly Renew air bags.

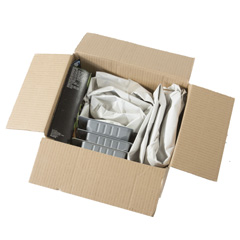

- The Renew air bags offer the right protection for the products that Mirka packs and ships. This way, Mirka prevents damage to its products and minimises the number of returns. This reduces costs and environmental impact by minimising landfill, fuel and energy.

- Each packing station is equipped with its own machine in an ergonomic top fill configuration. This set up creates more space for the packers.

The Result

![]()

SUSTAINABLE AIR CUSHIONS

-

The Renew film contains minimum 50% recycled consumer waste and is itself 100% recyclable. Moreover, it reduces the CO2 footprint by 52%. Renew airbags are therefore a sustainable alternative to standard airbags.

![]()

HAPPY EMPLOYEES

-

The compact MINI PAK'R V3 Top fill saves space at the workstations. This allows the packers to move around more freely, which enhances employee satisfaction and productivity.

![]()

HIGH PRODUCTIVITY & EFFICIENCY

- Ergonomic workstations lead to a higher productivity

-

The new sealing technology of the MINI PAK'R V3 ensures longer operating time and less maintenance.

What our Customer Says

Richard Tattum, Site Manager EDC, Mirka Belgium Logistics NV

"We were looking for a sustainable, but protective void fill solution. Pregis and Topa were the partners that immediately understood what we were looking for.”

We make sustainable choices in our business and in our products. Also when it comes to shipping. This means that we want to have our products optimally protected during shipping, but with the most sustainable solution.”

Our partner Topa Packaging together with supplier Pregis looked at our needs. The result was clear: the AirSpeed Renew was exactly what we needed. We started testing and indeed, it proved what they predicted: maximum product protection and our carbon footprint reduced 35% compared to our previous air cushions!”