WSSN: Packing efficiently with both air and paper at the same packing table | Case Study

WSSN (WebShop Service Nederland) needed to be flexible in meeting the packaging needs of their customers. Traditionally they pack with air but some customers also wanted the option to pack with paper.

The Challenge

WSSN (WebShop Service Nederland) relieves here customers of their worries by taking the processing of their orders off their hands. From stock management to packing and shipping.

WSSN needed to be flexible in meeting the packaging needs of their customers. Traditionally they pack with air but some customers also wanted the option to pack with paper.

They were therefore looking for a solution where their packers had easy access to both air and paper packaging materials.

The solution offered had to result in cost savings. This concerned both the consumables and the packaging process.

The Solution

The solution offered by Pregis involves a hybrid arrangement combining air cushion packaging, paper pads and paper void fill.

Line-up 1

- 1 x Packmaster Pro fanfold which supplies 4 packing tables with paper pads via a 1 bin system.

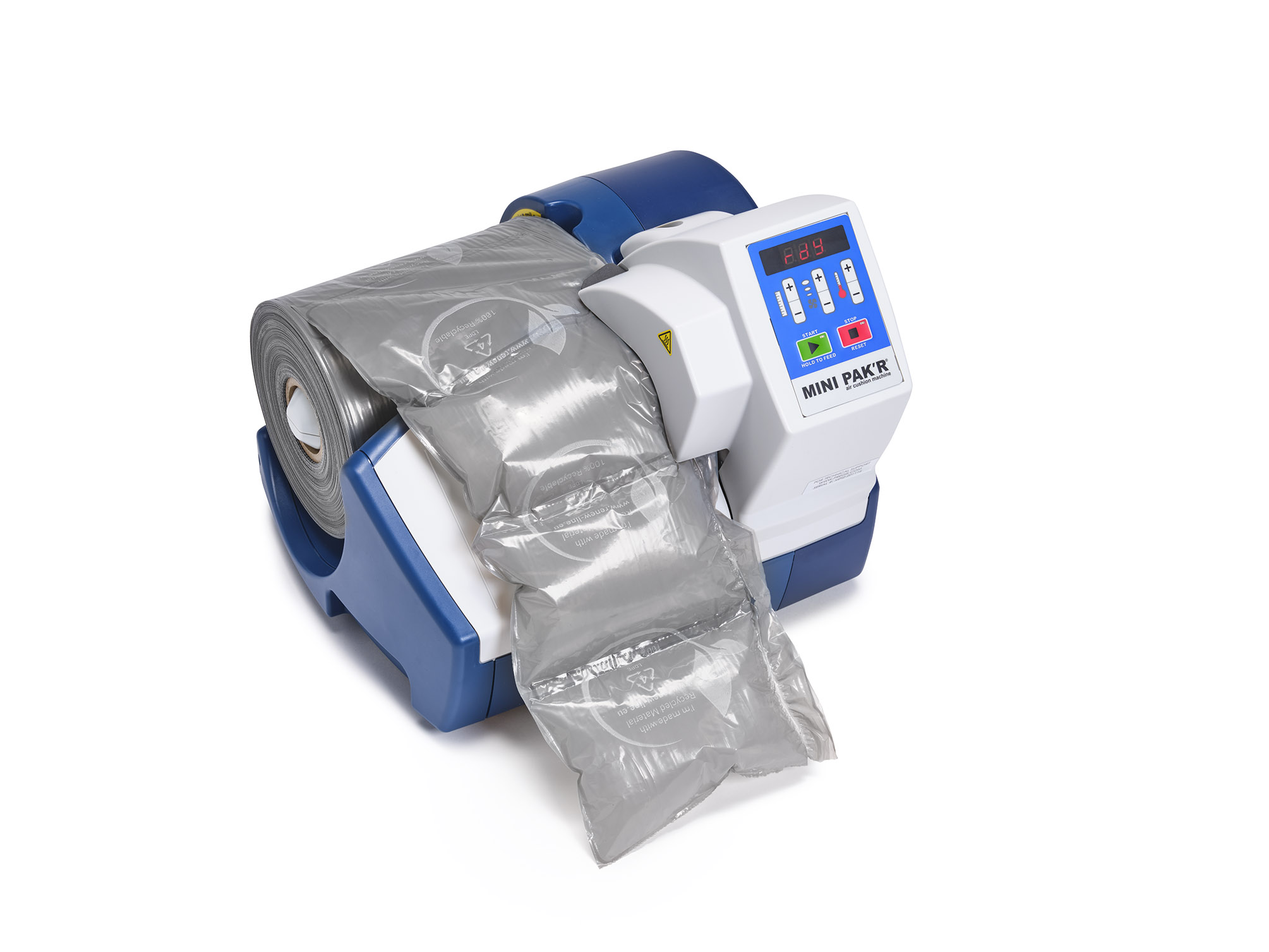

- To supply the same packing tables with air cushions, these are equipped with each a MINI PAK'R V3 top-fill.

Line-up 2

- 2 MINI PAK'R V3 top-fills provide 4 packing tables with air cushions.

- 2 of these packing tables are also equipped with a Quantum for paper void fill.

The Result

![]()

OPTIMAL PACKAGING

-

Pregis offered to carry out a pack comparison. This showed that the consumption of packaging materials could be reduced by 15-20% by opting for a combination of paper and air.

-

The optimum packaging method can be chosen for each item to prevent damage during transport.

![]()

HIGH PRODUCTIVITY & EFFICIENCY

-

In addition to savings in packaging materials, Pregis also saw the potential for savings by rearranging the space.

-

By making both paper packaging materials and air cushions available at the same packing table, walking distances are reduced and packing efficiency increased.

![]()

WIN-WIN SITUATION

-

As the packers of WSSN were mainly experienced in packing with air cushions, Pregis offered a workshop "packing with paper".

-

This created a win-win situation for all parties involved. The employees of WSSN feel comfortable packing with paper and the products of the customers of WSSN are guaranteed to be optimally packed.